A Simple And Low-Cost Method For Fabrication Of Non-Planar PDMS Microfluidic Channel

##plugins.themes.bootstrap3.article.main##

Abstract

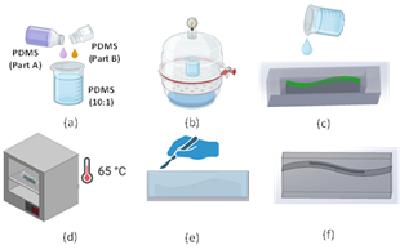

This research introduces a micromilling-based method for fabricating prototypes of poly(methyl methacrylate) (PMMA). This approach enables rapid prototyping of non-planar polydimethylsiloxane (PDMS) microfluidic channels, which are difficult to fabricate using traditional soft lithography methods. To achieve high fidelity, we improve the surface quality of the PMMA molds by systematically optimizing key machining parameters, including spindle speed, feed rate, and cutting depth. These optimized conditions are subsequently applied to CNC machining of complex three-dimensional curved geometries. Using a partial-curing method, the resulting PDMS devices achieve robust bonding strengths of up to 184 kPa without plasma treatment or specialized apparatus. This method offers a cost-efficient and accessible alternative for fabricating intricate non-planar microfluidic systems, markedly enhancing the design versatility and application prospects of PDMS-based platforms.

##plugins.themes.bootstrap3.article.details##

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.